If you’re responsible for the smooth operation of warehouse operations across your organization, you know that managing inventory, machines, people, and resources efficiently while meeting tight delivery deadlines means that you need to have resilience in your supply chain. To help companies like yours execute mission-critical manufacturing and distribution processes without interruptions, we recently announced a preview for cloud and edge scale unit add-ins for Dynamics 365 Supply Chain management.

So how can your company benefit from cloud and edge scale units? One effective tactic is to place scale units near the location where production work is done—whether that’s in the cloud or right inside the four walls of the warehouse facility. That way, you can take advantage of the dedicated capacity that scale units provide.

Monogram Foods Solutions is a leading manufacturer and marketer of value-added meat products, snacks, and appetizers. Their team is participating in the preview. As noted here, they’re having great success with scale units:

“Our frozen goods warehouse has a tight time constrained picking process, and it is critical for our warehouse team to have a consistent and reliably quick response throughout the entire picking operation. The architectural design of the solution ensures that these critical warehouse workloads are isolated from the rest of our operations, eliminating points of contention during these time-sensitive processes.”

Transition to workloads for resilient warehouse execution

You can find more information about what scale units are and how to set them up for the warehouse execution workload in the documentation. In this blog post, we’re going to take a deeper look into how to implement dedicated scale units.

With the workload for warehouse execution, you can transition the execution phase of warehouse processes into dedicated scale units. The workload defines the scope of business processes, data, and policies including rules, validation, and ownership for what runs in the scale unit. Inbound, outbound, and other warehouse management processes have been split into decoupled phases for planning, execution, receiving, and shipping.

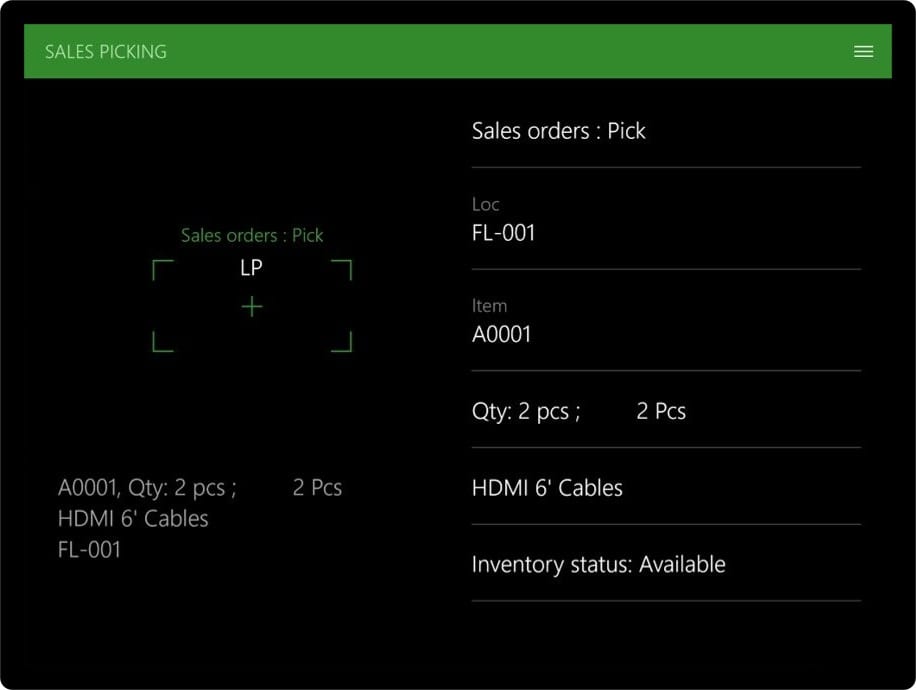

After you configure the workload, the workers on the warehouse floor continue to go through the work, like choosing the mobile warehouse management experience, connected directly to the dedicated processing capacity in the scale unit.

Hybrid multi-node topology makes it all work

In the hybrid multi-node topology, individual nodes are responsible for pieces in the distribution processes. The hub supports data management, warehouse process management, and release of orders to the warehouse and as well as some finalization steps, depending on the scenario.

For inbound warehouse processes, the responsibility of the workload on the scale unit begins when the purchasing agent releases purchase orders to the warehouse. It uses records of the new type of warehouse orders to trigger the work for the warehouse clerks on the floor.

A copy of the relevant inventory is available on the scale unit and is constantly kept in sync with the central inventory. For temporarily disconnected edge scale units, this local inventory acts as a local cache, so the warehouse worker can complete work like put-away, independently of the scale unit.

As soon as warehouse workers have completed a task, the cloud hub runs the next steps. In the public preview, this includes the generation of the receipts for the receiving process. The transition happens instantaneously if the (edge) scale unit has connectivity.

Sales clerks find support in outbound warehouse processes when releasing sales orders to the warehouse. The workload in the scale unit will apply the relevant wave processing method and warehouse workers will perform tasks like picking. From there, the shipping process will take over. Tasks like the packing slip generation will still continue on the cloud hub in the preview version.

The workload for warehouse execution supports additional operations that run fully on the scale unit. Warehouse workers can inquire about items, item locations, and license plates, as well as move items within the warehouse.

Take away: Scale units help you to build resilient warehouse execution

Dynamics 365 Supply Chain Management transitions to a multi-node supply chain topology. This allows customers to build resilience by deploying scale units in the cloud or on the edge with built-in redundancy and flexible management.

The warehouse execution workloads in the public preview show how business processes support resilience in this hybrid multi-node topology for supply chain management. Microsoft will continue finetuning the responsibilities of workloads in scale units based on customer feedback to address the most common use cases out of the box.

In the upcoming Spring release updates, you will find several important enhancements. Warehouse workers in outbound scenarios can perform simple picking and loading work for transfer orders on scale units. Label printing will be available on scale units, including support for wave labels. Further enhancements include cluster picking, wave processing for shipments, change of workers, cancelation, location movement, and completion of work for sales and transfer orders.

Next steps

Learn more about cloud and edge scale units and other important topics in the documentation for Dynamics 365 Supply Chain Management .